The very definition of the word "sluice" can be summarized as an artificial channel for controlling water. Since water is the main tool all prospectors use to separate their gold from their dirt, the more control you have over it the better. Water isn't the easiest force of nature to master and all you have to do is look around to see that. Massive dams, rain gutters, storm drains and windshield wipers, it's all around us all the time! When it comes to gold panning and prospecting, those who learn to control the water best will yield the best results. That is primarily why there are so many different sluice box designs! There are several factors one must consider when building or buying what they deem to be the best sluice boxes. The flow of water is critical! Everything from how fast, how much, and how it behaves as it flows down are absolutely critical factors. Looking past these very important issues, one must also consider the construction and use of materials of their sluice boxes. Things like oil, rust, and improper design must be avoided at all costs!

The Technical Side of Sluice Boxes.

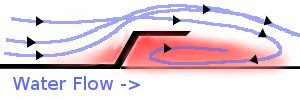

I've never been too good with physics or engineering so its a real shame that the dynamics of water and how it behaves as it travels through a sluice, is a topic that is JAM PACKED full of wonderful physics and hydrodynamics. The principle purpose of using water in our sluice boxes, long toms, rocker boxes, or any other type of water based gold separation, is to organize the materials we've dug up from heaviest to lightest and then discard the light stuff. When it comes to sluice boxes the main principles that allow them to work so effectively are their ability to create low pressure water zones that allow the gold to settle to the bottom and become trapped by water eddies or back currents. These eddies and back currents allow the material being trapped in their low pressure vortex to dance about continually without letting them escape back into the main stream of water. This "dancing" or agitation of the material is absolutely crucial for upgrading and concentration of the heavier materials like black sand or gold. It allows the lighter gravel and blond sands to be washed away as the black sand and heavies take their place and push them out into the main flow of water.The way these back eddies are created in sluice boxes change from design to design and some seem to work better than others. This is particularly true when it comes to finding very fine gold. The primary tool that seems to be fairly consistent throughout the designs is having large riffles. An obstruction for the water to flow over and pressurize. On the downstream side of the riffle will be a low pressure zone where back eddies will form and heavy materials will be deposited. Highlighted red in the picture below are the low pressure zones that hide after and potentially immediately before each riffle. It is in the main red area where gravel and heavy materials will swirl around letting the heavy materials settle and replace the lighter stuff.

Making sure the material swirls in this area without being washed clean is a bit of an art. You have to consider the speed and flow of the water as well as the design of the riffles in your sluice boxes. If you're making your own sluice don't be overly concerned about the design or science involved here, all you need to know is that gold is heaviest and you absolutely need those agitating back eddies to catch gold. This effect scales down for finer gold as well. Many sluice box companies use a fine expanded metal mesh such as the one featured below.

Making sure the material swirls in this area without being washed clean is a bit of an art. You have to consider the speed and flow of the water as well as the design of the riffles in your sluice boxes. If you're making your own sluice don't be overly concerned about the design or science involved here, all you need to know is that gold is heaviest and you absolutely need those agitating back eddies to catch gold. This effect scales down for finer gold as well. Many sluice box companies use a fine expanded metal mesh such as the one featured below. It does the same thing as the big riffles but catches smaller pieces and offers a much larger overall surface area in which to catch gold. You can come buy this stuff pretty cheap and even free if you know where to look. It is best placed under the big riffles of your sluice boxes to ensure maximum efficiency for catching both course and fine gold throughout.

It does the same thing as the big riffles but catches smaller pieces and offers a much larger overall surface area in which to catch gold. You can come buy this stuff pretty cheap and even free if you know where to look. It is best placed under the big riffles of your sluice boxes to ensure maximum efficiency for catching both course and fine gold throughout.The Three Basic Parts to Most Sluice Boxes.

I say most sluice boxes because there are some simplified designs that work very well without one or two of these basic principles.- Firstly, most modern metal and plastic sluice boxes have what's called a slick plate. There may be many other names for it but its not important. Its function however, is! The slick plate is either where you initially place your material, or immediately after it. It is where the water from the stream makes contact and starts doing the sorting for you. This slick plate area is nothing special to look at and it's usually a flat surface in which the water flow is slower and unobstructed. Some people put down rubber "v" matting to help catch nuggets or big gold for a couple seconds. This lets you know if your flow and water speed are in the right zone as well as if the spot you're digging in is baring any gold for you. It's usually located at the start of the sluice in the widest part or just after. The slick plate allows the material to become saturated with water and then slowly washed down into the sluice box before it can pick up too much speed. Sluice boxes with this feature often allow for better recovery of fine gold since there is less likelihood of large clumps of dirt or air bubbles catching and stealing gold away from you.

- Moving on we have the aforementioned riffles. They don't really need anymore explaining other than they are the primary workings of sluice boxes.

- Finally we've got our catch mats! while which material is best is a hotly debated topic on more gold panning forums, many have had success with materials as simple as walk in and welcome mats you can buy from any local department store. Other ideas include astro turf and carpeting. This is the sluice box's final chance to catch fine gold particles and with any luck at all the gold that's been knocked out of the main water flow by our riffle systems will settle nicely into our catch mat and remain stuck untill its time to clean it all out. Again, there is a bit of a science to which material to use but a good general rule is to use something that lets the water wash through it well enough to remove any really light materials but retain the heaviest ones.

Construction of Sluice Boxes.

As I was just saying, there are all kinds of different sluice box designs, both plastic and metal. However each designs generally have their own pro's and con's. There are some brands out there that have few pro's and many con's but generally speaking, you get what you pay for. Well established brands are worth the money in most cases. That doesn't mean you should be afraid to try new prospecting tools or equipment so long as your money permits it. There have been many a one-off and custom type designs that have bested some heavy hitting major brand name designs. In that regard, you're best bet is to do your research, ask around, and above all, stick to the known brands if you're a beginner so there's less that can go wrong.When it comes to metal designs one key thing you must remember is that it's likely in more than one piece. Corrosion of the metal can reign havoc on your sluice boxes. You may not be able to separate the riffles from the catch mat without losing concentrates, or you the riffles might not sit right allowing for poor hydrodynamics in the sluice! Either way, you're going to lose gold, so make sure you've got stainless, aluminum, or brass constructs. Sluice boxes aren't cheap these days with the recent spike in gold prices so you don't want to be wasting your hard earned money on any prospecting equipment that's going to seize up or malfunction in the near future.

Another important thing to consider is how easy your sluice boxes are to clean! This can be an excellent time to lose gold as well! An easily cleaned sluice should consist of no more than two screws holding the riffles and catch mats in the trough. This allows for easy and quick removal of the riffles and a thorough cleaning of your removable catch mat. Yes removable, it has to be!

If you're deciding to go the route of building your own sluice box, keep in mind the things mentioned here. The hydrodynamics and agitation of the material without gold loss is without a doubt the most important factor. A good proper running sluice should clear itself of a shovel full of material in 3-5 full seconds. Bigger rocks should roll out on their own with the occasional prod to help it along, and the slope of your equipment should be set somewhere around 5 degrees.

Be creative with your design and choice of materials. A light and durable designs is almost always preferred over a heavy mass production type. Avoid corrosion sensitive materials, and keep in mind that you're running rocks and gravel through its trough over and over and over. Those riffles and slicks plates are going to take a beating over time.

Thats about it for the Sluice Box Super Guide so good luck and have fun!

![Reblog this post [with Zemanta]](http://img.zemanta.com/reblog_e.png?x-id=68a1239a-5ffb-496c-af90-797e166664f3)

![Reblog this post [with Zemanta]](http://img.zemanta.com/reblog_e.png?x-id=2eb7c41c-b596-4a00-b6f7-4eadeb6248b6)

![Reblog this post [with Zemanta]](http://img.zemanta.com/reblog_e.png?x-id=58c138c6-e0a1-4dff-a591-42cf0f6d1f76)

![Reblog this post [with Zemanta]](http://img.zemanta.com/reblog_e.png?x-id=956c7e6c-3ff4-4c7e-98d3-a2b935d04512)